A Comprehensive Guide to Selecting IC and BGA Sockets: Meeting Your Diverse Needs

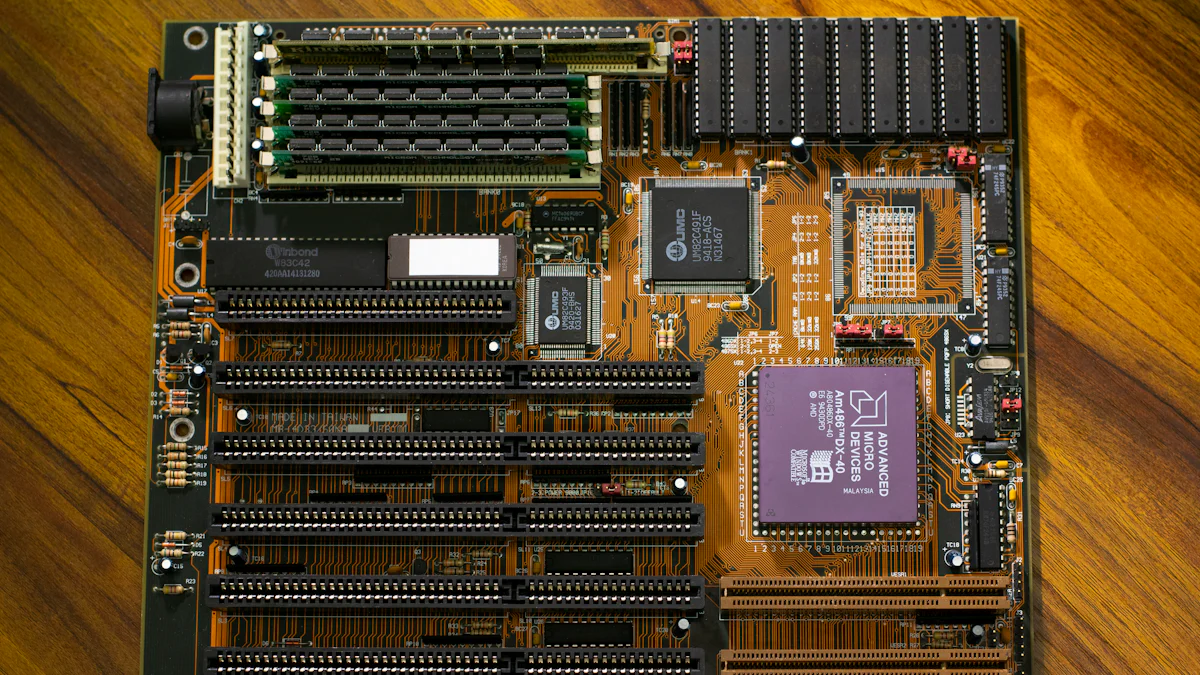

In the development and maintenance of electronic products, IC sockets and BGA sockets play a crucial role. They facilitate the connection and replacement of integrated circuits, enhancing efficiency and reducing costs. However, for those new to these products, choosing the right socket can be confusing. This article aims to provide a comprehensive guide to selecting IC and BGA sockets, helping you find the perfect product to meet your needs.

Understanding Your Needs

Before selecting a socket, it's essential to clarify your specific requirements. Different applications and integrated circuit types may require different socket types. Here are some common factors to consider:

Package Type: Common package types include DIP, SOIC, PLCC, QFP, and BGA. Choose a socket compatible with the package type of your integrated circuit.

Pin Count: Ensure that the number of pins on the socket matches the number of pins on the integrated circuit.

Pitch: The spacing between the pins on the socket should match the spacing between the pins on the integrated circuit.

Material: Common socket materials include plastic and ceramic. Choose a material suitable for your application environment, such as a ceramic socket for high-temperature environments.

Features: Some sockets may have special features, such as low-profile sockets or test sockets. Select the appropriate socket features based on your needs.

Common Types of IC Sockets

DIP (Dual In-line Package) socket: Suitable for DIP-packaged integrated circuits, with pins arranged in a straight line.

SOIC (Small Outline Integrated Circuit) socket: Suitable for SOIC-packaged integrated circuits, with pins arranged in a small arc and a compact size.

PLCC (Plastic Leaded Chip Carrier) socket: Suitable for PLCC-packaged integrated circuits, with pins extending from the four sides of the chip and a square or rectangular package.

QFP (Quad Flat Package) socket: Suitable for QFP-packaged integrated circuits, with square-arranged pins and a smaller pitch, suitable for high-density packaging.

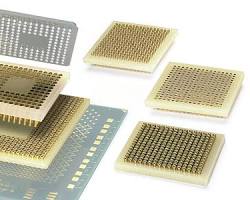

Special Features of BGA Sockets

BGA (Ball Grid Array) socket: Suitable for BGA-packaged integrated circuits, with solder balls as pins directly soldered to the PCB. BGA sockets facilitate testing and rework of BGA chips.

Selecting a Reliable Supplier

Choosing a reputable socket supplier is crucial. They can provide high-quality products, professional technical support, and excellent after-sales service. Before purchasing, we recommend consulting with the supplier's technical staff to ensure the product you choose meets your application requirements.

Conclusion

IC and BGA sockets are essential tools for electronic product development and maintenance. By reading this guide, you will have a better understanding of the different types of sockets and their applications.

See Also

Top Recommendations for Crimping Tools by Experts

Key Technology Trends Shaping the Connector Market

Exploring Various Small Form Factor Pluggable Connectors

Insights on Circular Connectors for Informed Decisions

Exploring Modular Connectors' Reliability in Industrial Automation