Understanding Different Types of Crimping Tools

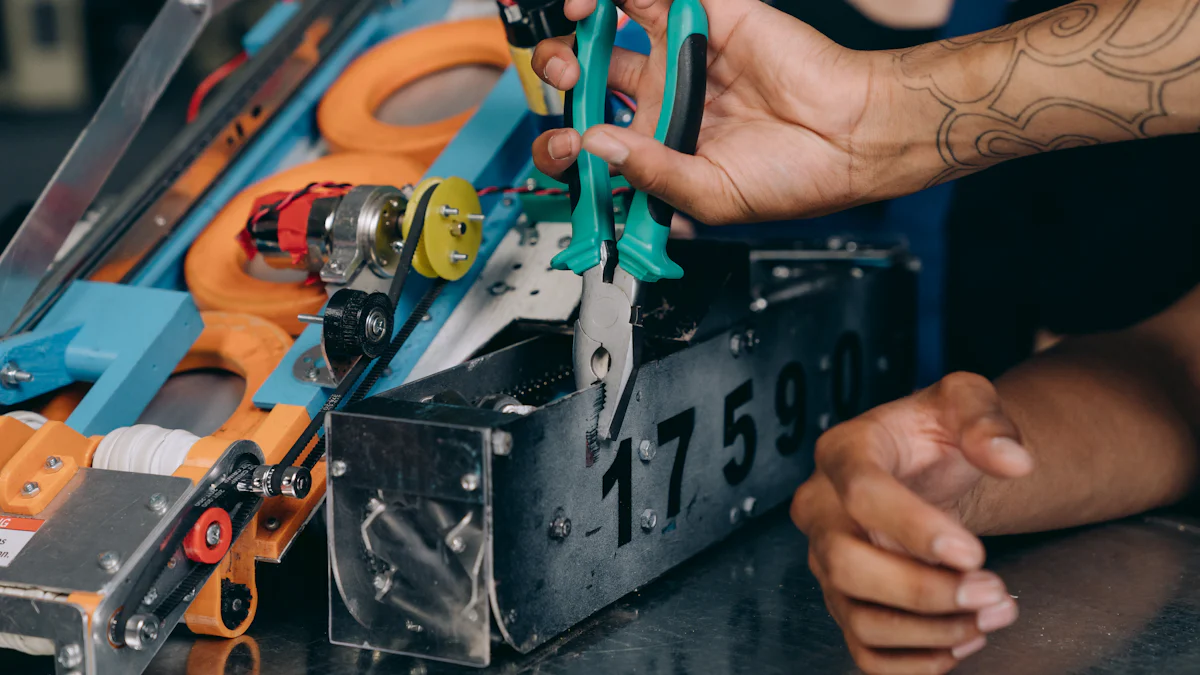

Crimping involves joining two components by deforming one or both to hold them together. This process is crucial in various sectors, including electronics, automotive, and telecommunications. You rely on crimping to ensure secure and reliable connections. The industry has evolved with technological advancements, offering a range of crimper types to suit different needs. From the versatile hand-held tools to the robust auto crimper, each type serves specific applications. Understanding these tools helps you choose the right one for your tasks, enhancing efficiency and precision.

Exploring Crimper Types

Hand-held Crimping Tools

Description and Uses

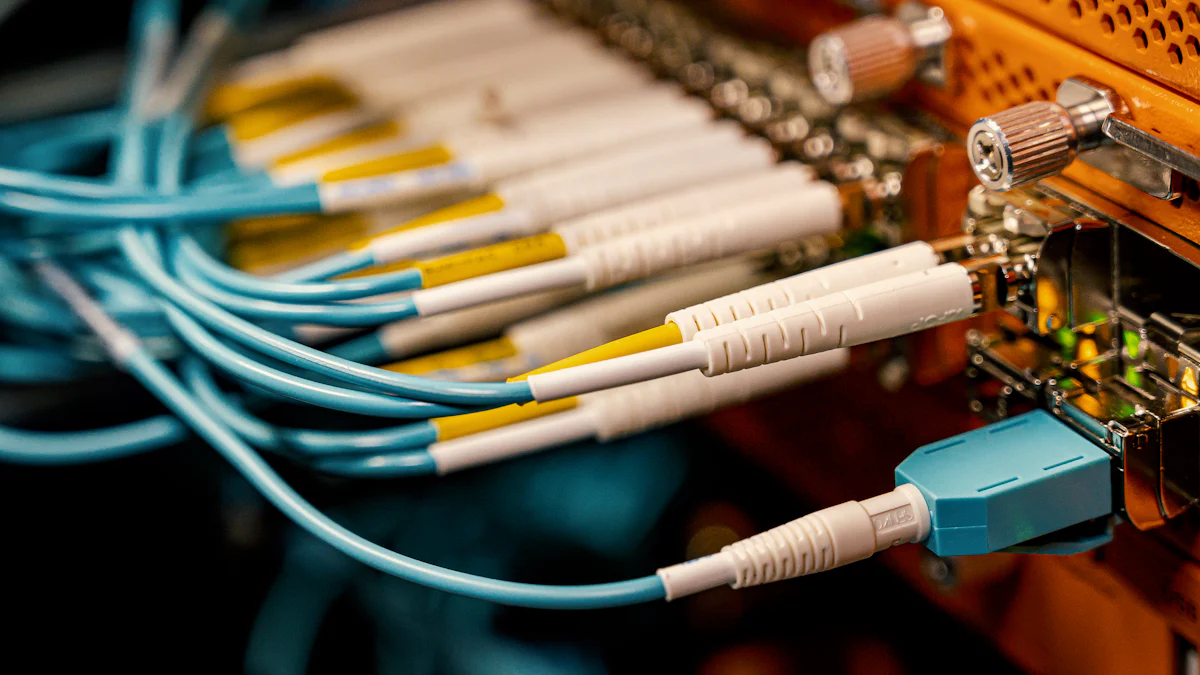

Hand-held crimping tools are versatile and portable, making them ideal for light-duty tasks. You can use these tools to crimp connectors onto wires in various applications, such as electronics and telecommunications. They are easy to operate and often come with interchangeable jaws to accommodate different terminal sizes.

Advantages

Portability: You can easily carry hand-held crimpers to different job sites.

Affordability: These tools are generally less expensive compared to other crimper types.

Ease of Use: They require minimal training to operate effectively.

Limitations

Limited Force: Hand-held crimpers may not provide enough force for heavy-duty applications.

Manual Effort: You need to apply physical effort, which can be tiring over extended periods.

Examples: Auto Crimpers, RJ45 Crimping Tools

Auto Crimpers: These are designed for automotive applications, allowing you to handle various connector types efficiently.

RJ45 Crimping Tools: Essential for networking tasks, these tools help you create Ethernet connections with ease.

Electrical Crimping Tools

Description and Uses

Electrical crimping tools are specifically designed for attaching connectors to electrical wires. They ensure secure and reliable connections, which are crucial in electrical installations and repairs.

Advantages

Consistency: These tools provide uniform crimps, reducing the risk of connection failures.

Efficiency: You can complete tasks quickly, saving time on large projects.

Limitations

Cost: Electrical crimping tools can be more expensive than manual options.

Power Dependency: They require a power source, limiting their portability.

Examples: Specific Models

Crimper Electric: This model offers consistent crimps and is powered by electricity, making it suitable for high-volume tasks.

Electric Hydraulic Crimping Tool: Combines the benefits of hydraulic pressure with electric power for enhanced performance.

Hydraulic Crimping Tools

Description and Uses

Hydraulic crimping tools use hydraulic pressure to create strong and reliable connections. They are ideal for heavy-duty applications, such as crimping large cables and connectors.

Advantages

High Force: These tools provide significant crimping force, making them suitable for tough materials.

Precision: Hydraulic tools offer precise control, ensuring accurate crimps every time.

Limitations

Weight: Hydraulic crimpers can be heavy, making them less portable.

Cost: They are generally more expensive than manual or electrical options.

Examples: Hydraulic Wire Crimping Tools

Hydraulic Wire Crimping Tool: This tool delivers powerful crimps for large cables, ensuring secure connections in industrial settings.

Portable Hydraulic Crimping Tool: Offers the flexibility of being handheld or bench-mounted, providing versatility for various tasks.

Pneumatic and Benchtop Crimping Tools

Pneumatic Crimping Tools

Pneumatic crimping tools operate using compressed air, making them a powerful option for high-volume crimping tasks. You can find these tools particularly useful in industrial settings where speed and efficiency are crucial. With the touch of a button, pneumatic crimpers deliver precise force, ensuring uniform crimps every time. This feature enhances both the mechanical and electrical performance of your applications.

Advantages:

Ease of Use: Pneumatic crimpers require minimal manual effort, reducing fatigue during extended use.

Consistency: They provide consistent pressure, resulting in reliable crimps.

Speed: These tools can complete tasks quickly, making them ideal for large projects.

Limitations:

Power Source Dependency: You need a constant air supply, which can limit portability.

Initial Cost: Pneumatic crimpers can be more expensive upfront compared to manual options.

Examples:

DMC Pneumatic Indent Crimp Tool: This lightweight and compact tool is suitable for both handheld and bench use. It's often used in proprietary and military programs, offering flexibility and precision.

Benchtop Crimping Tools

Benchtop crimping tools are stationary devices that provide stability and precision for crimping tasks. You can use these tools for applications requiring meticulous attention to detail, such as in laboratory or production environments. Benchtop crimpers often come with adjustable settings, allowing you to customize the crimping process to suit specific needs.

Advantages:

Precision: These tools offer high accuracy, ensuring perfect crimps.

Stability: The stationary design provides a stable platform for consistent results.

Versatility: Many models include interchangeable dies to accommodate various terminal sizes.

Limitations:

Lack of Portability: Being stationary, they are not suitable for on-the-go tasks.

Space Requirement: You need dedicated space for setup and operation.

Examples:

Mountable Pneumatic Crimp Tools: These tools can be clamped onto a workbench, providing a flexible and effortless crimping solution. They are air-powered and often connected to an operational switch for ease of use.

Understanding these crimper types helps you select the right tool for your specific needs, whether you require the speed of a pneumatic machine or the precision of a benchtop model.

In summary, understanding the various crimper types empowers you to make informed decisions. Hand-held crimpers offer portability and affordability for light tasks. Electrical crimpers ensure consistent connections, ideal for electrical installations. Hydraulic tools provide high force for heavy-duty applications. Pneumatic crimpers deliver speed and efficiency, while benchtop models offer precision and stability. Choose based on your specific needs, whether it's the portability of a hand crimper or the power of a hydraulic wire crimping tool. Each type serves unique purposes, enhancing your work's efficiency and reliability.

See Also

Understanding the Purpose of Crimping Tools

Best Hydraulic Hose Crimpers for Any Job

Comparing Conventional Low Voltage Solutions with Flexible DC Power Distribution